Marking, Engraving and Labeling

There are 3 procedures which, from a laser technology point of view, overlap considerably. They are therefore often combined and usually carried out with the same equipment.

Marking

Marking enables the application of complex geometries.

Engraving

Laser engraving is a surface treatment with optical or tactile changes

Labeling

Labeling describes the application of numbers and characters to objects.

Cosmetics industry

Explore innovation in cosmetics production: our latest project has resulted in a ground-breaking system that conjures up geometric shapes and intricate structures on lipstick packaging with the utmost precision. This not only sets visual accents, but also gives each packaging a unique feel – for an unforgettable brand experience. Maximum flexibility, creative freedom and flawless quality – this is the new standard in the finishing of cosmetic products.

Medical equipment

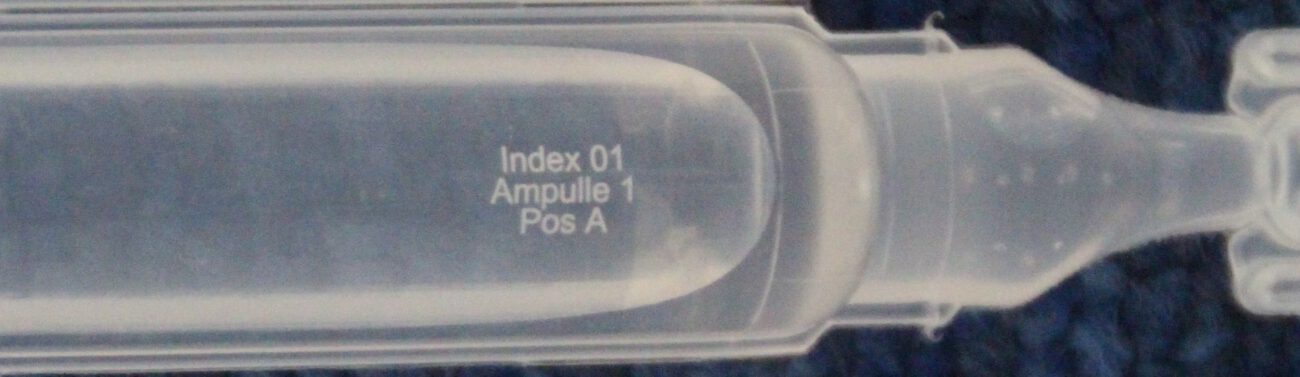

The labeling of ampoules requires absolute precision. Every marking must be razor-sharp and perfectly legible without affecting the material surface. This is the only way to maintain the integrity of the ampoule and reliably prevent possible contamination of the contents. Put your trust in our expertise – for safe, clear and contamination-free labeling that meets the highest quality standards. The labeling of ampoules plays a decisive role in patient safety, compliance with legal regulations and seamless traceability. It is also essential for maintaining hygiene and infection control standards.

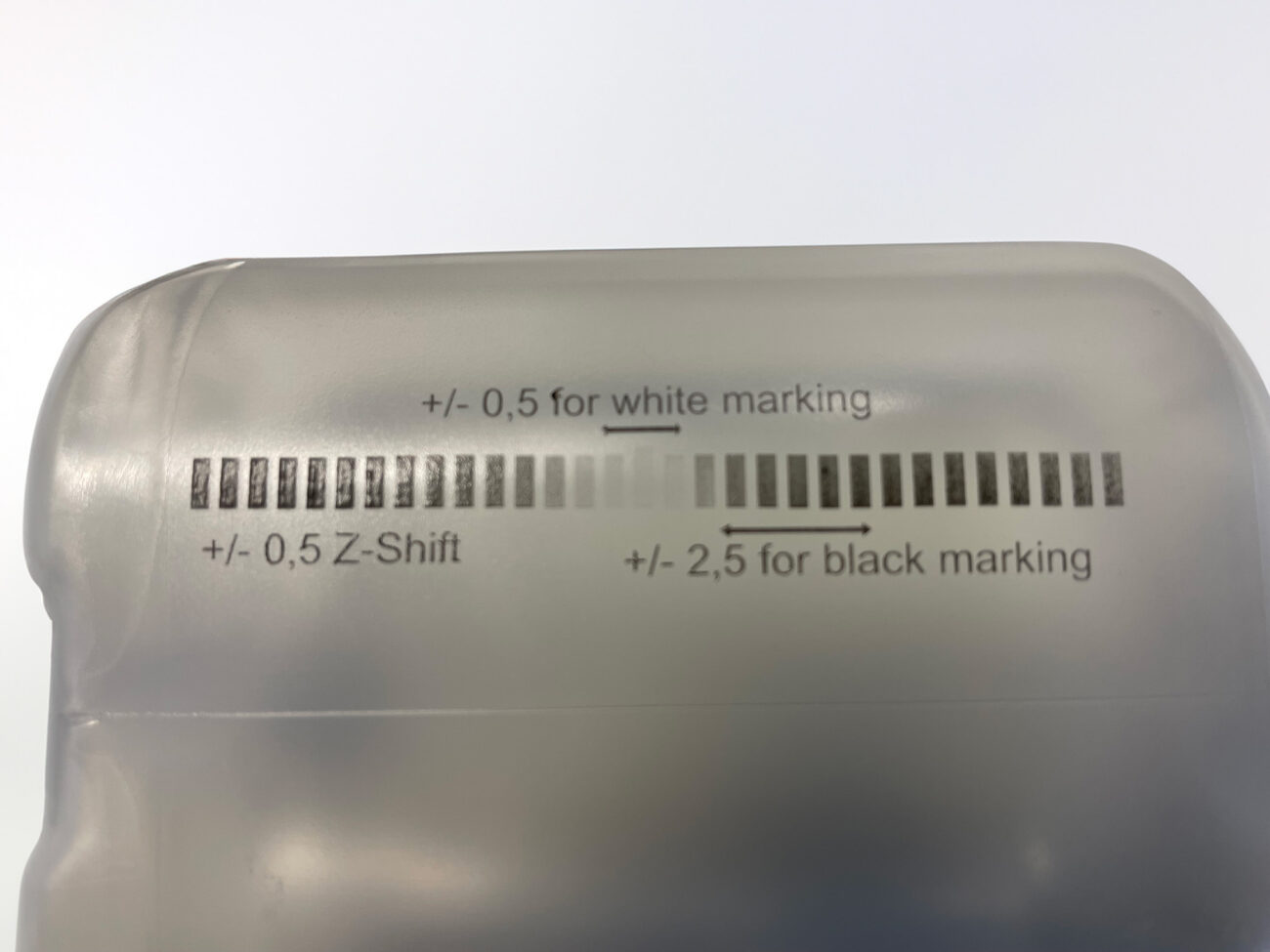

The manufacture of diagnostic equipment places the highest demands on precision and quality. Our process guarantees that the material is gently removed from the carrier layer without leaving any residue and without damaging it. At the same time, we meet the strictest dimensional accuracy requirements within the narrowest tolerances. You can rely on our expertise to meet the highest standards of precision and reliability.

Industry

Enhance your products to perfection with our high-precision laser system. Our technology makes it possible to place even complex designs and detailed information on cylindrical surfaces in a razor-sharp and permanent manner. Laser marking not only ensures excellent legibility, but also uncompromising material protection.

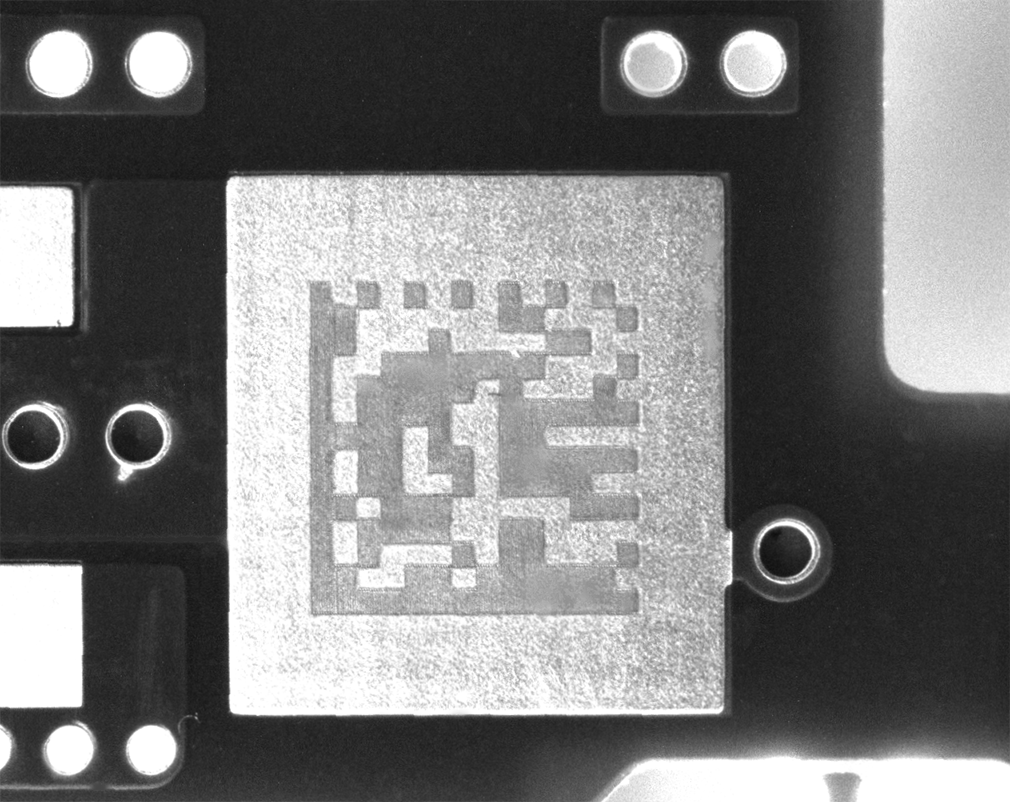

Maximize your efficiency with our versatile laser system that enables effortless marking on a wide range of materials in microchip and circuit board technology. Whether it’s intricate structures or complex details, our system delivers precise and durable markings that meet the highest standards.

We offer you the opportunity to implement markings in the range of just a few hundred micrometres with ease and precision. Rely on our expertise to realize even the smallest and most demanding markings with unsurpassed sharpness and reliability. Ideal for applications where every detail counts.

Marking, Engraving, Labeling

These are 3 procedures which, from a laser technology point of view, overlap considerably. They are therefore often combined and usually carried out with the same equipment.

Marking

Marking with simple and complex geometries, up to letter and character sequences. Examples are listed below:

A laser-generated data matrix is razor-sharp and can be easily converted with any suitable reader.

Ceramic, such as this high-quality writing instrument, can also be inscribed in black and filigree thanks to the variety of available parameters.

Engraving

Laser engraving is a surface treatment with optical or tactile changes. Examples are listed below:

The anodized layer is removed by evaporation and aluminium oxide is formed in the atmosphere.

“Night-and-Day” marking for a vehicle console. The part consists of a black painted translucent white plastic. By selectively removing the paint layer, the lettering appears white both in incident and transmitted light.

Labeling

Lettering is the application of numbers and characters. Examples are listed below:

Marking of bronze parts. Using special laser parameters, the surface is roughened considerably and metal particles adhere to the processed surface. This creates a contrast to the surrounding surface and the marking appears dark.

This medal is highly polished. The marking is created by slightly roughening the surface to prevent the surface from reflecting.

Marking

Marking with simple and complex geometries, up to letter and character sequences. Examples are listed below:

A laser-generated data matrix is razor-sharp and can be easily converted with any suitable reader.

Marking is possible on many materials, e.g. hard rubber, due to discoloration of the surface.

Ceramic, such as this high-quality writing instrument, can also be inscribed in black and filigree thanks to the variety of available parameters.

Engraving

Laser engraving is a surface treatment with optical or tactile changes. Examples are listed below:

The anodized layer is removed by evaporation and aluminium oxide is formed in the atmosphere.

In the case of coated textiles, the layer is removed and the gloss of the surface is eliminated. The color of the marking depends on the nature of the material.

“Night-and-Day” marking for a vehicle console. The part consists of a black painted translucent white plastic. By selectively removing the paint layer, the lettering appears white both in incident and transmitted light.

Labeling

Lettering is the application of numbers and characters. Examples are listed below:

Marking of bronze parts. Using special laser parameters, the surface is roughened considerably and metal particles adhere to the processed surface. This creates a contrast to the surrounding surface and the marking appears dark.

With leather, the color pigments are more or less dissolved out and you even get a marking in different shades.

This medal is highly polished. The marking is created by slightly roughening the surface to prevent the surface from reflecting.