Industry

Experience the future of pipe cutting with our state-of-the-art pipe cutting system! Thanks to innovative laser beam technology, you can achieve unparalleled precision and efficiency with every cut. Whether for thin or thick tubes, our system delivers perfect results with minimal effort.

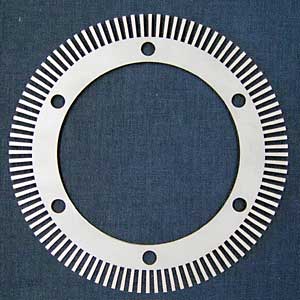

Every detail counts in the world of measurement technology. Our cutting systems are specially designed to cut parts with the highest precision – for measuring purposes where absolute accuracy is essential. Equipped with advanced components, our systems guarantee accurate cutting results and maximum reliability.

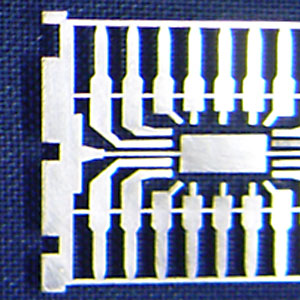

Experience how delicately cut parts, such as our precise ears of corn, become real eye-catchers thanks to our subsequent electropolishing. The careful processing gives the parts an exceptionally attractive, shiny finish that emphasizes their fine workmanship.

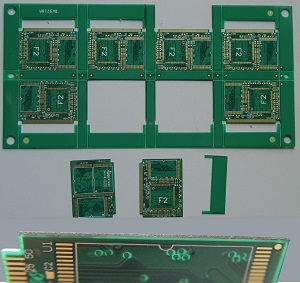

PCB substrate materials often present a challenge during laser cutting, as the cut surfaces tend to carbonize and undesirable conductive connections can occur. With our specially developed cutting system, this problem is a thing of the past. Our technology guarantees cut surfaces of the highest quality – clean, precise and free from contamination. Choose our solution for safe and reliable results in your PCB production.

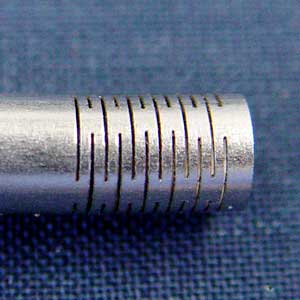

Optimize your production with our innovative cutting system, which has been specially developed for cylindrical parts. The optional rotary device allows you to tilt the rotary axis in any direction to achieve perfect cuts from all angles. This versatility allows you to perform precise machining and adjustments that were previously difficult to achieve.