Expertise

We have decades of experience in the development and construction of special laser technology equipment. This experience enables us to offer a wide range of laser processing from micro to macro processing.

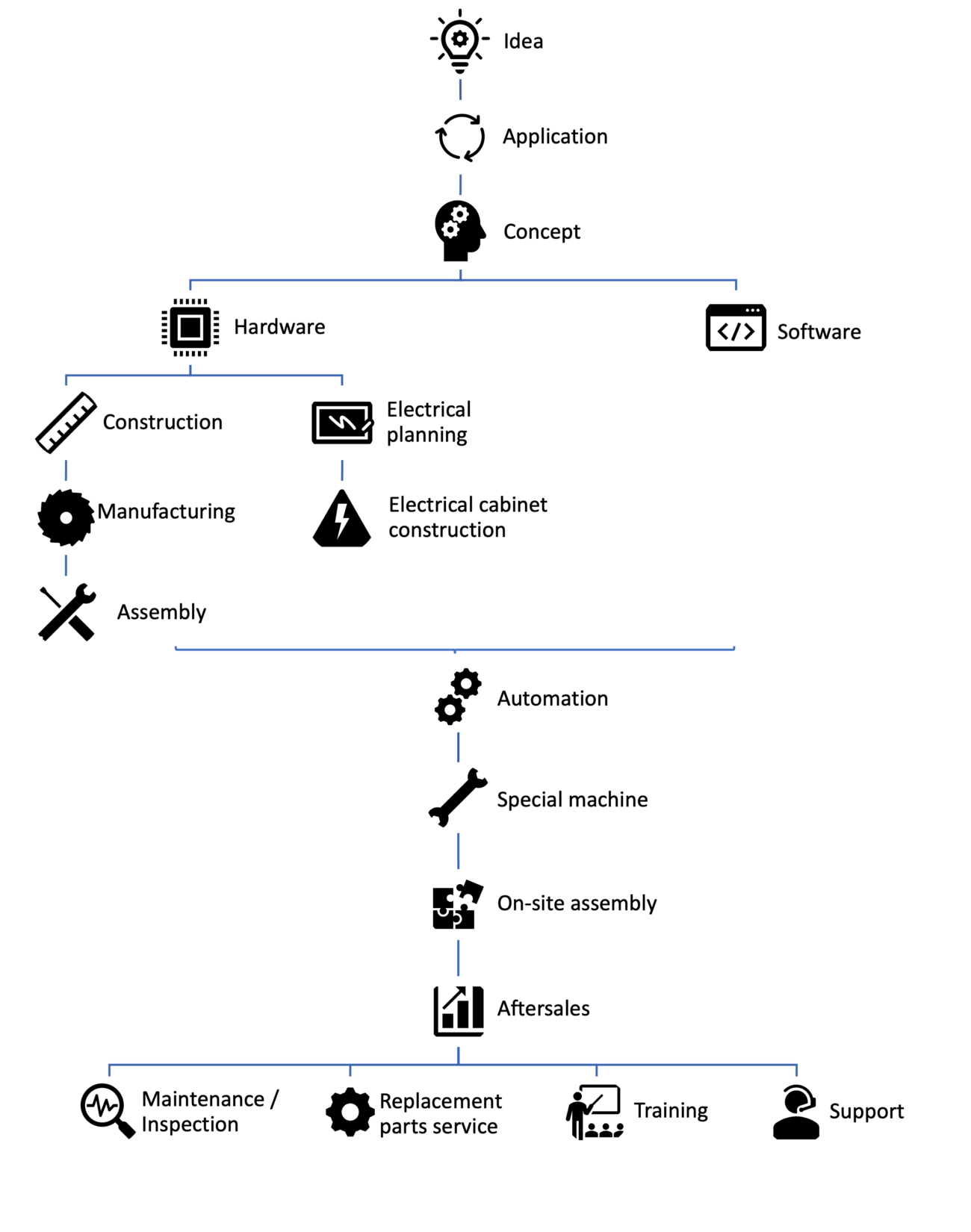

The systems are developed and manufactured according to the customer’s ideas and requirements. In order to realize the requirements, the following steps of the development chain are developed by ourselves:

- Machine design

- Production of machine parts

- Electrical planning

- Electrical construction

- Software

The quality of the respective application is evaluated during the development process in our application laboratory.

The individual steps of the development process are illustrated in the following diagram.

Development process:

History and laser experiences

| Year | Milestones | |

|---|---|---|

| 1968 | Second harmonic Nd:glass = 530 nm > Second harmonic ruby = 347 nm> Total frequency Nd:glass + ruby = 420 nm> | |

| 1978 | PW-Nd:YAG-Laser, 1,0 J@10 Hz | |

| 1980 | Laser adjustment machines for mechanical filters (3-shift operation) | |

| 1983 | CW-QS-Nd:YAG laser, 5 Watt@25 kHz, single mode | |

| 1985 | Laser adjustment machines for high-ohm resistors in the giga? range (3-shift operation) | |

| 1987 | Laser adjustment machine for quartz filters (center frequency, bandwidth, symmetry) | |

| 1988 | Establishment of a laser application center in the Academy of Sciences | |

| 1990 | Reorientation after reunification | |

| 1992 | Construction of a laser marking system for contract work | |

| 1996 | Construction of a laser marking system for sale | |

| 1998 | Founding of Laser-Mikrotechnologie Dr. Kieburg GmbH | |

| 1998 | Construction of our own laser marking systems for contract work | |

| 1999 | Start of production of LMBS laser marking systems for sale | |

| 2000 | Construction of our own laser welding system for contract work | |

| 2002 | Construction of our own laser micro-processing system for contract work | |

| 2004 | Development of your own labeling software multiCAM | |

| 2007 | Manufacturing laser welding module LMSS and laser marking module LMBS basic | |

| 2008 | Tabletop device for laser marking LMBS desktop | |

| 2009 | Start of production of micro-processing systems LMBS micro | |

| 2010 | Entry into the production of special laser technology equipment with automation, image recognition, online measurement technology, monitoring systems, etc. | |

| 2011 | Decoupling wage work as an independent Dr. Kieburg Lasertech-Services GmbH www.lasertech-services.de | |

| 2012 | Entry into ultra-short pulse laser technology, purchase of a picosecond laser | |

| 2013 | Construction of a tri-chromatic processing station | |

| 2014 | Construction of a cutting system for electrode sheets for Li batteries | |

| 2015 | Construction of a cutting-welding marking system |